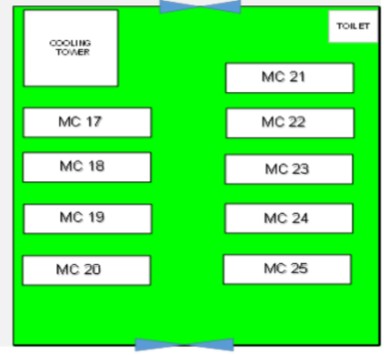

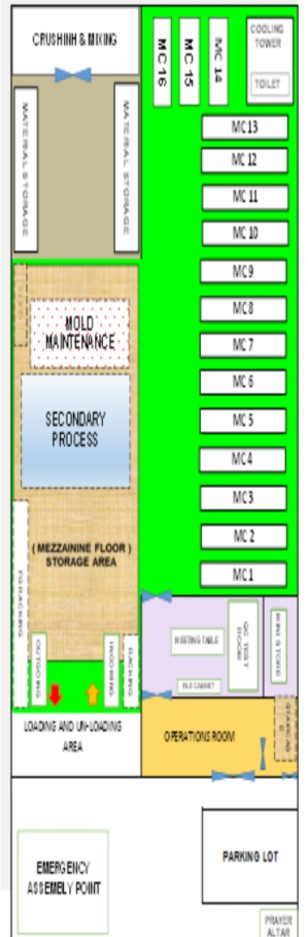

The efficiency of production depends on how well the various machines; production facilities and employee’s amenities are located in a factory.

For PND, our factory layout is an important decision as it represents long-term commitment. We provide the optimum relationship among output, floor area and manufacturing process. PND facilitates the production process, minimizes material handling, time and cost, and allows flexibility of operations, easy production flow, makes economic use of the building.

Our layout promotes effective utilization of manpower, and provides for employee’s convenience safety, comfort at work, maximum exposure to natural light and ventilation. It is also important because it affects the flow of material and processes, labour efficiency, supervision and control, use of space and expansion possibilities etc.

Factory Snapshots

INJECTION MOULDING MACHINES

ASSEMBLY PROCESS

PAD PRINTERS

HOT STAMPING

ULTRASONIC MACHINES

ULTRASONIC MACHINES

QC MEASURING EQUIPMENT

MOULD CARRIERS

LATHE MACHINE

MOULD CRANE

MOULD MAINTENANCE TABLE

MATERIAL STORE

FINISHED PRODUCT STORE

DEFECT TRAINING & QC INSPECTION

OUTGOING INSPECTION